Goodmorning.

Today we will delve into the world of drill bit identification. Essential if you want to use the right drill bit for the right purpose. Looking in your toolbox and wondering how you got a collection of so many drill bits and should you buy new ones or try to use the ones you already own?

Yes, there are many types and forms of drill bits for many different uses. If you’ve never drilled into any kind of material or even if you’re a professional then this list may be a handy guide to identifying drill bits stuffed into your toolbox and when they are best used.

So before we start, he’s a quick run down of the main types of drill bits.

|

|

|

|

|

Metal drill bits |

Wood drill bits |

Masonry drill bits |

Tile/glass drill bits |

As I say, there are many different drill bits however they fit into the following families; Wood and timber and plastics, Masonry and stone, Tiles and glass, Metals and other materials.

Metal drill bits

Metal drill bits

Traditional split point metal drill bits were originally designed to be used with milling machines, lathes or pillar drills. Their use was adopted by hand rotary drills over the years, however this is why most drill bits snap. With the use of a machine the factors of keeping the drill bit straight, constant pressure and exact speed can be controlled, whereas while hand drilling all these factors are constantly changing no matter how professional or for how many years you have used drill bits.

In general Metal cutting drill bits can also be used on many other materials, such as wood, timber, plastic, various metals up to and including steel, rubber and other more dense materials.

You may find that some drill bits have an additional very thin coating of TiN (Titanium Nitride), or TiCN (Titanium CarboNitride). This is a very thin layer and will be worn away after a time. and is to aid with wear resistance.

Tip: When using a metal cutting bit to cut metal always use a lubricant to aid with the cut. The purpose of the lubricant is to cut down on friction between the drill and the material being cut. Therefore cutting down heat and helping the drill to cut through the material.

Warning: NEVER use WD40! WD40 (WD40 – stands for Water Displacing formula 40) creates a thin film of oil over whatever you’ve sprayed it on and stops squeaks, but will not help with your drilling lubrication. As soon as the drill gets hot the WD40 will dissipate. Drilling lubricant is specifically for purpose.

Wood drill bits

Unlike the metal drill bit, there’s many different types of bit that can drill wood and timber. We’ll go through most of them in this post. Also unlike wood no lubricant is used with wood, although beeswax can be used to lubricate anything cutting through wood.

Masonry drill bits

Once again with the masonry drill bit, lubricant isn’t really used. Sometimes water is used with the harder types of slate or more dense materials.

Glass/Tile drill bits

Unlike masonry drill bits many glass and tile drill bits are ostensibly used with water as a lubricant.

So on to our topic. The A to Z of drill bits and what they are used for and how to spot them.

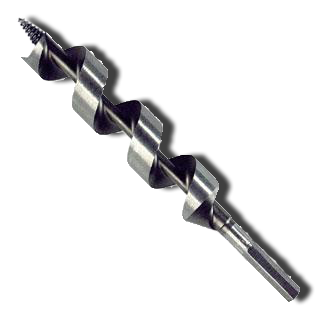

A is for Auger

The auger drill bit is basically a wood bit. Using the principle of the archimedes screw the drill takes the material from the front of the drill to the rear, it has a small screw type point which burrows into the wood or timber keeping the drill in the wood while the cutting face shaves off the wood.

B is for Brad Point.

The brad point, dowel or lip and spur bit, is similar in design to the auger bit. The tip is the major difference, as it has three points, one on each of the initial cutting faces and one in the middle of the tip. Unlike the auger this bit does not pull the bit into the wood.

C is for Centre drill.

The centre drill has a tip on both sides and is basically used for countersinking. Also this is our first HSS drill bit, so can be used with steel, other metals, woods and plastics. Generally if it’s HSS (meaning High Speed Steel) then it will cut a multitude of different materials.

C is for Cobalt drill bits.

This drill bit is a metal drilling bit, but is for harder materials, HSCo High speed cobalt.

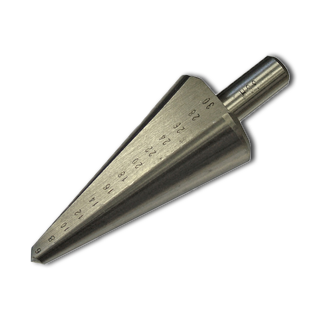

C is for Conical drill.

The conical or cone drill like the step drill is used for making holes bigger. Usually only for sheet material, otherwise you will end up with a tapered hole. Also another steel and other metals drill bit, although may only have one cutting face. The cone drill is more accurate with its cut than the step drill as the step drill has to forced through the material down each step.

C is for Counterbore.

Similar to the countersink, but for socket cap screws so they fit flush with a flat surface. Usually used together with a standard drill bit to drill the center hole to length.

C is for Countersink.

Now, like wood drill bits there are many different types and for different purposes. All either for wood or for metal. There are just four examples above. The two on the left are metal countersinks (A three flute HSS, then a deburring countersink) and the two on the right are dedicated wood countersinks (A rose head countersink and a drill countersink combination).

D is for Diamond drill.

There’s a lot of myths concerning diamond drill bits. Yes diamond is hard so potentially would make a very good drill bit, however it doesn’t have a good cutting edge to cut steel, wood and so on. It’s used for cutting tiles, glass and similar materials, and it’s used abrasively, like a carbide grit holesaw or core drill, which is also diamond.

They could never get a sharp enough edge, and big enough diamond to cut into hardened steel to make it worthwhile. The bit would cost a fortune!

F is for Flat bit.

The flat bit is probably the most common drill bit around. It’s for wood and usually has the size printed on it. It has two cutting edges on either side and a point at the front for keeping the drill steady in the material. It’s also known as the spade bit.

There is also a type of flat bit which is a cross between an auger and a flat bit, called an expansive bit. This has a fitting attached so the size of the drill bit can be changed to the size of the hole you need it to be.

F is for Forstner bit.

The Forstner drill bit is another version of wood bit. However it has more teeth around the cutting edge, aiding to a cleaner finish. Or as in the example above just a much larger cutting edge.

G is for Glass or tile Drill.

Easily recognised because of the brazed on carbide tip and the look of the tip being flat without any noticable cutting edge. Was originally invented to be used by hand, and very slowly with a lot of pressure. Lubricated with water to cool the tip down. A common problem with using this drill bit is running the drill too fast without any lubrication.

A good tip for starting the drill on the slippery tile or glass is to put scotch tape or cellotape across the tile where you want to drill, then the drill will grip on the tape until it starts to cut into the material.

H is for Hexagon shank drill bits.

These type of drill bits come in many types, including pozi, philips, slotted and actually metal, masonry and wood drill bits. The hexagon shank helps the drill bit to stop spinning in the chuck or can be used in a bit holder type driver, usually magnetic. It’s not recommended to use screwdriver bits in a power drill as these are not clutched to use them, this will lead to the screw head or the driver bit being rounded off or damaged.

H is for Holesaw bits.

Used in combination with drill bits to create holes, this type of drill/saw has many different types from Bi-metal; cutting through steel sheet, plastics, other metals and wood. Cobalt; cutting into harder materials and steels. TCT grit; cutting into very hard materials. Diamond grit; cutting into tiles, glass, slate, ceramics and similar materials.

H is for HSS (high speed steel) drill bits.

The most common type of Steel and other metal cutting drill bit. Before HSS was invented they used Carbon steel drill bits to try to drill metals, but this was found to be next to useless. The picture shows an HSS morse tapered shank drill bit.

M is for Masonry drill bits.

Once again there are quite a few different types of masonry drill bits, later you’ll see SDS which uses a clip-in system. Basically masonry drill bits have a carbide tip brazed onto the front of the drill shaft. Very similar to the SDS, TCT and glass drill bits. However, the masonry drill bit has it’s faces and flutes ground in a different way so it can drill into masonry, breeze block, concrete, asphelt and many other similar abrasive surfaces.

M is for Metal drill bits.

Basically because this section is so large, I’ve clumped them all in together. I could probably do a post just on different types of Metal drill bits, from double ended body drills (which are basically drill bits on both ends), to HSS, to HSco, to Tin coatings, Ticn coatings, fast spiral(for Stainless Steel and hard materials.) , slow spiral(for softer materials like brass) Blacksmith’s drill bits which have a reduced shank, left hand or right handed spirals the list goes on. Starting with Carbon steel (very flimsy drill bits) all the way up to armour piercing (you have to pass a MOD test to be able to buy these, and need to account for them) There are many drill bits around, the above picture is of a TiN coating on a HSS drill bit, one of the popular drill bits around, the TiN coating is suppose to disburse the heat and extend the life of the drill bit.

M is for Multi-construction or a does-it-all drill bit.

![]()

Basically this drill bit has been designed to drill through everything except tiles/glass. Masonry, steel, wood, plastic. There is only one problem with this drill type, and that is that once you’ve cut throught masonry of any kind, you will file the edge off and it won’t cut through wood, metal or plastic very well any more. Rendering the drill bit useless except for masonry.

S is for SawDrill.

The saw drill is an interesting bit. it has teeth one either side of it’s cutting flutes enabling it to saw through material sideways. Very useful for softer materials like wood and plastics or sheet materials.

S is for SDS Drill.

The SDS plus drill bit is probably the most common of SDS drills and is a push fit system fitting into a dedicated masonry drill. As well as masonry, there a bits that can drill into reinforced concrete and drill through the rebar material.

Once again there’s many myths and misunderstandings about what SDS stands for. It doesn’t mean “Special Direct System”, “slotted drive system” or “special direct system” as it was created in Germany by Bosch.

SDS actually stands for “Spannen Durch System” and was created by Bosch in the 1970’s, although Bosch international have changed its meaning in English speaking countries to to mean “special direct system” in order to keep the SDS title uniform across the world.

S is for Spot Weld Drill.

|

|

There are a few types of spot weld drill bits. The two above are the main versions. On the left is a drill bit guided spot weld drill. On the right is a HSCo (cobalt) drill bit which is harder than HSS. The drill on the right tends to only have a single flute. Both are used to go through the usually harder and/or thicker material of a weld or spot weld.

S is for StepDrill.

As stated above with the conedrill, the stepdrill is for opening holes in sheet material. The advantage of the stepdrill is that the steps on the drill are parallel, and therefore the hole won’t be tapered.

T is for TCT Precision drill.

Basically another drill for drilling very hard materials. Tungstan Carbide is man made and grown into drill tips, which like the tile/glass drill mentioned earlier are brazed onto a steel shaft. The major difference between the TCT and glass drill is the that the TCT drill has been sharpened and honed to a sharp edge on both cutting faces. This makes TCT bits one of the best drills for drilling very hard metal surfaces.

So there we have it! A comprehensive list of the available drill bits and how to tell them apart.

I shall add a new post to this in a couple of days that will have a close up of the different types of drill bit tips. Masonry, Steel, and wood.

I was recommended this blog by my cousin. I’m

not sure whether this post is written by him as no one else know such detailed about my difficulty.

You are amazing! Thanks!

Whoa lots of amazing advice.

Thanks to my father who shared with me on the topic of this blog, this web site is genuinely

awesome.

Hi

In the last few days I have found two drill bits with round swirly ends. One belonged to my Dad born 1910. The other fell out of an old makita bag purchased resale.

I am wondering what they are for.

Thanks! Did you ever do a post on different types of Metal drill bits (i.e., double ended body drills, to HSS, to HSco, to Tin coatings, Ticn coatings, fast spiral, slow spiral, Blacksmith’s drill bits, left hand or right handed spirals …)? I have some bits I’m trying to identify and didn’t see them on your list. I could send a pic with your email.

Hello there I am so excited I found your site, I really found you by mistake, while

I was looking on Google for something else, Regardless I am here now and would

just like to say cheers for a incredible post and a all round exciting blog (I also love the theme/design), I don’t have time to read it all at the

moment but I have bookmarked it and also added

your RSS feeds, so when I have time I will be back to read more, Please do

keep up the excellent work.

I spent a great deal of time to locate something such as this

Thank you for your hard work.

Thanks for this nice post. …

Thank you so much!

thank you web site admin

Woah! I’m really loving the template/theme of this

website. It’s simple, yet effective. A lot of times it’s

tough to get that “perfect balance” between user friendliness and visual appearance.

I must say that you’ve done a excellent job with this.

In addition, the blog loads very fast for me on Opera.

Exceptional Blog!

The truth is that if you want quality drill bits they aren’t ever cheap, if they are, you haven’t bought a quality drill bit at all. Think about it! If you’re buying a 12mm drill bit and paying €2.50, you’re going to get Een stukje kaas! (A piece of cheese…) Realistically, for a decent Dormer or Guhring 12mm drill bit you will be paying €15!! I know in England you are forced to price for jobs to include cheap tools and consumables that you use one off for the job, so obviously this comes into play when buying your 12mm metal drill bit. I like the idea of you going into more depth about metal drill bits, like someone posted before.

I like the helpful info you provided in your articles. I’ll bookmark your blog and check in again here

regularly.

Best of luck for the next article!

Wonderful work! This is the type of info that is meant

to be shared across the web. Shame on the seek engines for now

not positioning this higher!

Thanks =)

Hi! I could have sworn I’ve been to this blog before but after looking at

a few of the posts I realized it’s new to me. Regardless,

I’m definitely happy I came across it and I’ll be bookmarking it and checking back frequently!

Hey very interesting blog!

Now a post on how you know the diff btw hard metal and soft metal, and hard wood and soft wood. Im s chik so dont laugh. The only way i know how to tell aluminum from other silver metals is with a magnet. So if you have a hard metal but its real thin (like tin roofing), does it still require the same type of bit as drilling thru a thicker hard metal?

Lol ive been using wd40 as lub when drilling metal… But im only going thru thinner materials and seems to help than without. Guess I’ll go buy right kind

By the way, what kinda soap are you talking about…. Liquid or bar? Add a few kinds wld be great!!!

Thanks for your comments.

Generally Soft metal and hard metals are easy to gauge brass (shiny light yellow) being soft, and a high tensile steel (dull shiny grey) bolt being hard. Usually a professional will assume the material is hard and use the appropriate drill bit, until he finds the material isn’t. There are charts one called The Mohs Scale which tell you the generic hardness of metals that people use as a rule of thumb.

As far as wood is concerned there is another scale called the Janka hardness scale is basically a rating of force to embed a steel ball into the surface of the wood by a certain distance. Yeah good eh? Anyhow the more force needed the harder the wood is, some woods like Brazilian ebony are extremely dense and a superior drill bit will be required.

With lubricant if you have nothing else then yes, WD40 will do. But it evaporates, just leaving a residue on the surface of the material and not acting a coolant or lubricant between materials. As I say, it’s better than bare metal to metal. Even kitchen cooking oil is better than WD40 in my opinion, but nowhere as good as a mineral oil. The reason for the lubricant is to cool the materials down and prevent friction between the materials. Expensive (or cheap) drill bits will be made from molten steel and then hardened and tempered by a controlled heating and a cooling process making them harder than the material you’re drilling. If you don’t cool the materials while drilling them the drill will be de-tempered and will become softer again.

Thank you very much for the invitation :). Best wishes.

PS: How are you? I am from France 🙂

If I take a TCT bit and run it down a straight edge, can I cut a glass window pane? If I don’t have a glass cutting roller

This is a treasure-find for me. I have bits that I did not know how to use. Thanks!

Impressive blog post.

Accusharp cutting tools likes your blog.

Thank you for sharing with us.

I recently lost my husband and am at a loss as to how to even put a hanging basket up…We have a garage full of odds and ends, drill bits etc and things that no longer work. Thank you for this great site.

Hi! I’ve been reading your blog for some time now and finally

got the bravery to go ahead and give you a shout out from Austin Tx!

Just wanted to say keep up the good job!

Top grade!!!!

Hi everyone. My wife and I are happy we saw the posts. Ive been searching for this info for days and I will be telling my followers to swing on by. The other morning I was skipping through the search engines trying to find these answers. I just was led to thank you from the bottom of my heart for such a resource.

What interesting ideas..

Having read this I thought it was extremely enlightening.

I appreciate you taking the time and energy to put this information together.

thank u so much for this, i need to drill a hole for my new monitor and did not kno what to use. got hundruds of drills n dun kno what 1 to use

Nice post. Cant wait to see your next one.

That is very fascinating, You’re an overly skilled blogger.

I have joined your feed and look forward to searching for

extra of your great post. Also, I have shared your web site

in my social networks

Excellently)))))))

We are very happy having discovered this web blog, it is really the thing my friend and I have been searching for.

The information on the site is beneficial and appreciated and will assist my family and friends. It shows that everyone has a large amount of understanding concerning subjects on the site and other pages of information really show it.

Typically i’m not on the web all of the time however when I have some time im usually hunting for factual information. Three of my cohorts that have also picked up an interest in this because of what I have gathered about it and they will definitely be going to be visiting the web site since it is such an incredible discovery.

Do you have any video of that? I’d love to find out more details.

Hello Nam. We don’t have a video at present, but are definitely considering this in the future.

Thanks this was really helpful

I have a question. how can you tell what metal you are drilling? So I can pick the right drill bit.

Thanks for your question Annie, truthly It’s a process of elimination to determine the material you’re about to drill.

1. Colour – The first thing to do is look at the metal’s colour. Silver, platinum chromium and palladium will all have a bright white colour, Aluminium is slightly less white and more gray, Titanium will be a slightly more grey-white colour. Steel will have a silver dark-grey colour. Tin, pewter, lead and manganese are all be duller gray metals. Bronze is a dark orange/brownish colour, copper will be an orangey/yellow colour, brass will be even more yellow with a hint of orange, then gold will be a bright yellow colour.

Here’s a deeper look at the Colours of metals

2. Context. The next question is where is the metal, what does it look like and how much of it is there?

If the metal is your sink, it’s probably stainless steel or cast iron and it’s easy to tell these apart cast iron is usually black or very dark and Stainless steel is a silver grey colour.

Or if it’s a cup/tankard it’s either silver, silver plated or pewter. Then we go back to

3. Weight and quantity – if it’s a large piece of metal like a table, but it’s very light in weight then it’s probably aluminium. If it’s thick and heavy, grey silver then it’s probably steel or iron, if it’s a watery yellow it may have a zinc passivate or chromate coating and be steel underneath.

4. cost

Precious metals are obviously a lot more expensive than everyday Aluminium, iron or steel. Gold, Silver, Palladium, Platinum are all extremely expensive and it is usually obvious what they are as they’ll be in smaller quantities.

5. Is it magnetic? The next best thing to do is get a magnet (even a fridge door has a magnetic strip around the edge) and place the metal against it. If it’s magnetic then the metal you’re about to drill is most likely to be Iron or steel. Although there are a few other metals that are magnetic they are pretty rare in the home.

Other magnetic metals include; Nickel and Colbalt and in very rare cases Copper and Manganese.

So the bottom line is….working through these points in order

1. Colour; dark gray maybe..has paint on it so can’t tell 100%… 2. Context and 3. Weight; It’s large and it’s in the home, bought from DIY store and is pretty heavy 4. Cost £120 . 5. Is the metal magnetic…yes.

In this case it’s probably Iron, Steel, or some types of (duplex, ferretic or Martensitic) Stainless steel(this will be determined easier through price and quantity – if the difference is the expense then it’s probably Stainless steel). However, all three metals will take the same kind of drill bit!

Perhaps this should be turned into a post?

I congratulate, you were visited with an excellent idea

I have read several excellent stuff here. Definitely

bookmarking for revisiting. I wonder how

so much attempt you place to make this type of great informative website.

What’s up, just wanted to tell you, I liked this article.

It was inspiring. Keep on posting!

I’m truly enjoying the design and layout of your website.

It’s a very easy on the eyes which makes it much more pleasant for me to come here and visit more often.

Outstanding work!

This is a great site. I’m glad I found it I intend to return more often.

I absolutely love your blog and find a lot of your post’s

to be just what I’m looking for.

Again, awesome site!

Hi, I do think this is an excellent site. I stumbledupon it 😉 I am going to return yet again since I

book-marked it. Money and freedom is the

greatest way to change, may you be rich and continue to help

others.

Hey very interesting blog!

Good article. I’m experiencing a few of these issues

as well..

Very good article. I certainly appreciate this website.

Keep writing!

I’m impressed, I must say. Seldom do I come across a blog

that’s both equally educative and amusing, and let me tell you, you’ve hit the

nail on the head. The problem is something which too few men and women are speaking intelligently about.

I am very happy that I came across this during my hunt for

something concerning this.

I have been a tool and diemaker for about 45 years. I have drilled over at least one million holes. From a no. 80 bit up to 2 inches. And you know what ? I am still learning. I am 66 years old, and retired and still drilling holes. I can sharpen drills that cut better than store bought. Any questions? feel free to ask

An impressive share! I’ve just forwarded this onto a coworker who was doing a little research on this.

And he actually ordered me breakfast simply because I discovered

it for him… lol. So allow me to reword this….

Thank YOU for the meal!! But yeah, thanks for spending time to

talk about this subject here on your internet site.

thanks for the imformation it helped

Keep on writing, great job!

wonderful points. When would you suggest your next post will be about?

Great article.

Thanks very interesting blog!

hi!,I really like your writing very so much!

proportion we keep up a correspondence extra about your post on AOL?

I require an expert in this house to resolve my problem. May be that is you!

Taking a look forward to look you.

I’m impressed, I must say. Seldom do I come across a blog that’s equally educative

and amusing, and let me tell you, you have hit the nail on the head.

The issue is something that too few men and women are speaking intelligently about.

I’m very happy I found this during my search

for something relating to this.

I am impressewd wit this web site, real I am a fan.

Good way of telling, and nice piece of writing to get information regarding my presentation focus, which i am going

to present in institution of higher education.

First off I want to say awesome blog! Thank you!

Hey very interesting blog!

I couldn’t refrain from commenting. Well written!

Hey there, You’ve done a great job. I’ll certainly digg it and

personally recommend to my friends. I am sure they’ll be benefited

from this site.

this article is very useful, thank you for making a good article

Awesome advice. With thanks!

Wow, fantastic blog format! How long have you been running a blog for?

you make blogging look easy. The total look of your web site is magnificent,

as well as the content material!

I have actually shared this blog post along with my pals and coworkers.

It is actually also excellent to disperse

the word!

Keep this going please, great job!

Hi there to every one, since I am truly eager of reading this website’s post to be updated on a regular basis.

It contains nice material.

Terrific work! This is the kind of information that are meant to be shared across

the net. Shame on Google for no longer positioning this post higher!

Come on over and talk over with my web site . Thanks =)

Hi there! Someone in my Facebook group shared this website with us so I came to

check it out. I’m definitely enjoying the information.

I’m book-marking and will be tweeting this to my followers!

Great blog and brilliant design.

I think this iss among the most important info for me.

And i’m glad reading your article. But want to remark on some generazl things, The websitee style is wonderful, the articles iis realoly excellent : D.

Good job, cheers

thanks, interesting read

Great goods from you, man. I’ve understand your stuff

previous to and you are just too magnificent. I really like what you

have acquired here, really like what you are saying and the way in which you say it.

You make it entertaining and you still take care

of to keep it sensible. I can’t wait to read much more from you.

This is really a tremendous website.